LVT Flooring

- Home

- LVT Flooring

Your Trusted Supplier for Premium LVT Flooring

Founded in 2017, Qingdao Huanju New Material Co., Ltd is a professional source manufacturer specializing in SPC flooring, with over 12 years of industry expertise.

Our state-of-the-art production facility in Shandong Province spans 25,000 square meters, equipped with advanced automated production lines to ensure efficiency, precision, and consistent quality.

500+ Projects & Applications

Qingdao Huanju Classifications of LVT Flooring:

Dry Back: This type is relatively cheap.

Loose Lay: This type is relatively expensive.

Click.

Adhesive.

01

Dry Back

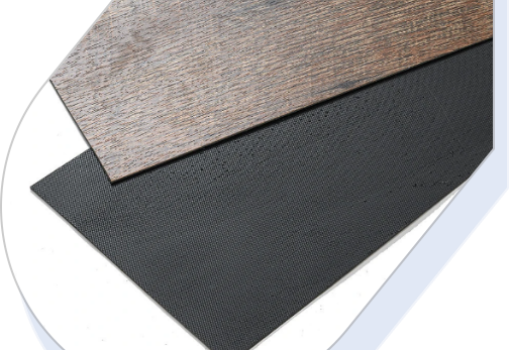

Dry Back LVT is a durable and stylish flooring option that is considered the cheapest among the LVT product categories. It mimics the look of natural materials like wood and stone.

The production process for Dry Back LVT includes several key steps:

Bottom & Middle Material are composed of polyvinyl Chloride and resin, lime powder, plasticizer, stabilizer, black carbon and other components.

Hot Pressing combines the wear layer, decorative layer, middle layer, and backing layer.

UV Coating and Annealing involves applying a UV coating to the surface of the wear layer to measure wear and scratch resistance, and to adjust luminosity and brightness.

Punching is performed.

Profiling is another step in the process.

Finally, the product undergoes Packing.

For installation, Dry Back LVT is also known as Adhesive/Glue Down.

02

Loose Lay

Loose Lay LVT is a durable and stylish flooring option that mimics the look of natural materials like wood and stone. It is considered the more expensive option among the LVT product categories.

The production process for Loose Lay LVT begins with the bottom and middle materials, which include polyvinyl chloride and resin, lime powder, plasticizer, stabilizer, and black carbon, among other ingredients.

These layers then undergo hot pressing, where the wear layer, decorative layer, middle layer, backing layer, and a Lune base/cross base are combined.

Following this, UV coating and annealing are applied to the surface of the wear layer to measure wear and scratch resistance and to adjust luminosity and brightness.

The material is then subjected to punching , followed by profiling.

Finally, the product is prepared for packing. Loose Lay is also a recognized installation method for LVT flooring.

03

Click

Click LVT is a durable and stylish flooring option that mimics the look of natural materials like wood and stone.

There are several types of click systems, including V-buckle 2G, U-buckle, 5G, 5Gi, and 4F.

The production process for Click LVT involves several stages.

It begins with the Bottom & Middle Material, which is composed of polyvinyl chloride and resin, lime powder, plasticizer, stabilizer, and black carbon, among other ingredients.

These materials then undergo hot pressing, combining the wear layer, decorative layer, middle layer, and backing layer.

Next, UV coating and annealing are applied to the surface of the wear layer; this step helps measure wear and scratch resistance and adjust luminosity and brightness.

Following this, punching is performed. A distinctive step for Click LVT is profiling, which includes the “click” mechanism. Finally, the product is prepared for packing.

Click is also listed as an installation method for LVT.

04

Adhesive

Adhesive LVT is a durable and stylish flooring option that mimics the look of natural materials like wood and stone.

The production process for Adhesive LVT involves several stages. It begins with the Bottom & Middle Material, which is composed of polyvinyl chloride and resin, lime powder, plasticizer, stabilizer, and black carbon, among other ingredients. These materials then undergo hot pressing, combining the wear layer, decorative layer, middle layer, and backing layer. Next, UV coating and annealing are applied to the surface of the wear layer; this step helps measure wear and scratch resistance and adjust luminosity and brightness. Following this, punching is performed. A distinctive step for Adhesive LVT is profiling, which includes the addition of centrifugal glue after trimming and chamfering. Finally, the product is prepared for packing. Adhesive is also listed as an installation method for LVT.

Production Capabilities & Customization

1. Raw Material Mixing and Calendering

The first step in LVT flooring production is the mixing and calendering of raw materials. This takes place in the bottom layer (middle layer) workshop.

The specific production process is as follows:

Polyvinyl chloride (PVC) resin powder, plasticizers, stabilizers, and carbon black are added to a mixer according to a predetermined formula. The machine automatically adds the plasticizer. After this, stone powder is added. The ingredients are then mixed thoroughly, and the blended mixture is transferred via a conveyor belt to an internal mixer for heating and mixing.

Inside the internal mixer, the machine kneads and folds the material. The raw powder then enters a set of rollers, where it is gradually formed through a calendering process. Finally, the material is cooled and cut into slabs.

Function of Each Raw Material:

Bottom layer materials are typically very tough and difficult to break. They are composed of PVC, calcium powder, and plasticizers.

Middle layer materials are more brittle. The combination of the tough bottom layer and the more brittle middle layer provides tensile strength, which helps prevent the plank from warping.

PVC resin powder: A non-toxic, odorless white powder with high chemical stability and good plasticity. While PVC is the most widely used polymer in the world, pure PVC is actually one of the most unstable. Its benefits are only realized after the addition of appropriate stabilizers and other additives.

Carbon black: The pigment with the strongest coloring and covering power. It is also the most stable pigment, with excellent resistance to heat, chemicals, and light.

Stone powder: Insoluble in water and soluble in acid, its main function is to increase opacity and improve the flexibility of the material.

Plasticizer: A nearly colorless, low-viscosity liquid. Since pure PVC is a hard material, adding a plasticizer makes the final plastic product soft, flexible, easy to bend and fold, and gives it good elasticity for shaping.

Stabilizer: This slows down chemical reactions, maintains chemical balance, reduces surface tension, and prevents decomposition from light, heat, or oxidation reactions, thus promoting product quality and stability.

2. Hot pressing

Hot press lamination is the second step in LVT flooring manufacturing. This process securely bonds all the core layers of the flooring into a single, cohesive, and rigid unit. You can imagine it like making a sandwich, but this “sandwich” is “baked” at high temperature and pressure, making it an inseparable whole.

The layers are arranged in a specific order on a steel plate: canvas, embossing plate, release film (matte film, high-temperature paper), bottom layer, middle layer, wear layer, decorative film, and another release film (matte film, high-temperature paper). A second steel plate is placed on top, and the entire stack is then sent to a hot press machine, where it is subjected to continuous heating and pressure. After a set period, the press is opened, the release films are peeled away, and the laminated flooring is formed.

Sometimes, a fiberglass layer is added between the two middle layers, depending on customer requirements.

The current range of vinyl floor surfaces includes:

Antique wood texture (BP texture), Hand scraped (hand scrape), Crystal, EIR (embossed-in-register), Slate, Random, Leather, and other patterns like slate texture and pearl texture.

The patterns and colors of the decorative film can be identified by the species of wood they imitate.

There are many types of decorative film, including wood grain, carpet, and stone patterns. Different types of film can be sourced based on customer requirements.

Vinyl flooring can have the same patterns and colors as laminate flooring but offers superior water resistance and ultra-high wear resistance that laminate cannot achieve.

The topmost layer is the wear layer, which varies in thickness from 0.07 to 1.0 mm. This thickness directly determines the level of wear resistance. A thickness of 0.3 mm is generally the standard for distinguishing between commercial and residential use.

Overall, the wear resistance of vinyl flooring is higher than that of other types of flooring. For example, a 1.0 mm thick wear layer can withstand 20,000 rotations under a CS-17 grinding wheel in a wear resistance test. Common wear layer thickness specifications are 0.1, 0.15, 0.2, 0.3, 0.5, and 0.7 mm.

3. UV coating and Annealing

The third step is UV coating and annealing.

The laminated flooring is placed on a conveyor belt, where a layer of UV coating is applied evenly by rollers. The boards are then exposed to ultraviolet light and sent into an oven to be baked. Once the coating is fully cured, the flooring is cooled in cold water. Finally, a cold air fan dries the surface water, and the boards are left to cure at room temperature.

The purpose of the UV lacquer is to enhance the floor’s gloss to meet customer specifications. The brightness of the floor is not directly related to the amount of UV lacquer used, but rather is controlled by the brightness level of the lacquer itself.

This process can be thought of as giving the flooring a layer of armor. It primarily focuses on the floor’s surface performance, providing exceptional resistance to abrasion, scratches, stains, and fading, which ensures the flooring remains beautiful and durable during daily use.

The purpose of annealing is to reinforce the shrinkage and warping resistance of the PVC flooring through the heating and cooling process on the production line. This process primarily focuses on the floor’s internal stability. During hot pressing and rapid curing, internal stress can build up within the flooring. Annealing allows this stress to be slowly released, bringing all the layers of the material into balance. This enhances the dimensional stability of the flooring, preventing future issues like warping, shrinking, or expanding.

4. Punching

The fourth step in the LVT flooring production process is punching (also known as die-cutting).

Punching is a critical forming process that precisely cuts the large, single panels—which have already undergone hot pressing, coating, and curing—into individual flooring planks. This step is crucial for determining the final dimensional accuracy and edge quality of the LVT flooring. Its importance is reflected in several key areas:

Dimensional Accuracy: The precision of the punching process directly determines if each plank is the exact same size. Consistent dimensions are essential for subsequent lock-groove milling and floor installation. If the dimensions are inaccurate, it can lead to large gaps or a failure to connect the planks during installation.

Edge Flatness: High-quality punching dies ensure that the edges of the planks are cut very flat and smooth, without burrs or tears. This provides a solid foundation for the subsequent beveling (edge trimming) process.

Production Efficiency: Punching machines enable automated and continuous production, which significantly boosts the efficiency of flooring manufacturing. It is an indispensable part of large-scale production.

5. Grooving

The fifth step is beveling and milling (also known as grooving).

These are two crucial processes in the LVT flooring production line. While both deal with the edges of the plank, their purposes are completely different. In short, milling is for installation, while beveling is for aesthetics.

Beveling is the process of angle-cutting or grinding the edges of the flooring to create a sloped bevel or a V-shaped groove.

Purpose: To enhance aesthetics and realism.

Visual Effect: Beveling mimics the authentic look of solid wood flooring. The distinct lines on the edges of each plank create a noticeable V-shaped joint when planks are installed together, giving the floor a layered and three-dimensional appearance.

Hiding Imperfections: The groove created by beveling can effectively hide subtle differences in height along the plank edges that may arise from punching or installation, making the overall floor lay flatter and more seamless.

Design Variety: Beveling comes in various forms, such as 2V bevels (beveled on the long sides only, to enhance a sense of length) or 4V bevels (beveled on all four sides, the most common style that best simulates a real wood effect).

Beveling is purely for aesthetics and enhancing the floor’s texture; it can even be done on glue-down LVT flooring.

Milling/Grooving is the process of using specialized equipment to machine the edges of the planks, creating the interlocking click system we are familiar with.

Purpose: To enable glue-free, quick installation.

Click System: Milling is specifically designed for click-lock LVT flooring. Precision milling cutters are used to shape complementary tongues and grooves on all four sides of the plank.

Seamless Connection: When installing the flooring, you simply connect the tongue of one plank into the groove of another to form a secure, seamless joint.

Convenient Installation: This design eliminates the need for adhesive, making the installation process more eco-friendly and significantly faster. It even allows for a DIY installation.

Removability: Click-lock flooring is easy to disassemble and reinstall, which is convenient for repairs or replacements.

The precision of the milling process is critical, as it directly determines how tight and secure the lock is and how flat the seams are after installation. Dry back and loose lay flooring do not require milling.

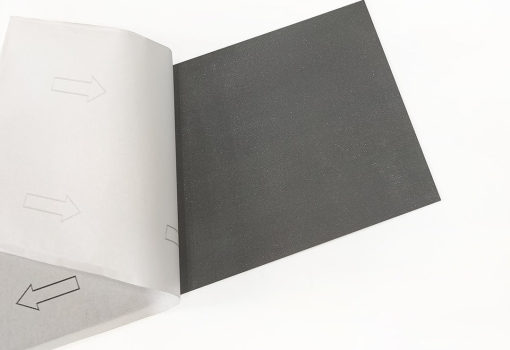

6. Packing

At every stage of production, rigorous quality testing is performed, including checks for dimensional stability, abrasion resistance, peel strength, and cosmetic defects.

Finally, qualified LVT flooring is packaged, typically in cartons and pallets, ready for shipment.

LVT flooring packaging is a two-person operation. One person performs the final inspection and cleaning before boxing. Their job is to specifically remove any defective products with obvious scuffs, scratches, foreign matter, stains, rounded corners, bubbles, color differences, discoloration, white edges, damaged locks, delamination, folded material, beveled corners, or broken corners. This is the final quality control checkpoint. The other person seals the boxes and verifies that the labels and shipping marks are accurate.

Why Us

01

Seasoned Industry Experience

Established in 2017, Qingdao Huanju New Material Co., Ltd. brings eight years of dedicated experience in SPC flooring manufacturing.

02

State-of-the-Art Production Facility

Our 13,000 square meter production base in Shandong houses fully automated production lines for extrusion, UV coating, cutting/grooving, silent pad application, and packaging. This ensures consistent quality and high output.

03

Impressive Production Capacity

We boast significant daily production capabilities, with our extrusion lines alone capable of producing at least 1500 square meters of 4mm SPC flooring in 24 hours.

04

Extensive Product Customization

We offer a wide range of customizable features including various thicknesses (3.5mm-7.5mm) , diverse surface textures , hundreds of color film patterns, customizable wear layer thicknesses , and flexible sizing from standard to large and small formats, as well as custom dimensions.

05

Advanced Functional Features

Our SPC flooring can be customized with UV coatings for various finishes (gloss, matte, semi-matte) , and includes options for integrated silent pads like IXPE (reducing noise by up to 18dB) and EVA for enhanced comfort.

06

Certified Quality & Rigorous Testing

All products comply with CE certification , and detailed SGS performance reports are available. We maintain strict quality control through various testing equipment, including solid densimeters, wear testers, tensile testing machines, and drying ovens, ensuring product stability, durability, and flatness.

07

Broad Application Versatility

Our SPC flooring is ideal for a diverse range of environments, including high-traffic commercial spaces (malls, offices, hotels) , residential homes (bedrooms, kitchens, bathrooms) , demanding medical and educational facilities (hospitals, schools) , and industrial/special purpose areas (workshops, gyms).

08

Customer-Centric Service & Global Reach

We cater specifically to B2B clients worldwide, including distributors, wholesalers, importers, brands, construction, and design companies. We offer swift sample delivery (7-10 days) , efficient bulk order lead times (approx. 25-30 days for 2500 sqm) , and provide customized packaging and secure palletized shipping.

What Our Clients Say About Us

Exceptional Quality, A Trustworthy Partner

We have collaborated with Qingdao Huanju for many years, and their SPC flooring quality has been consistently outstanding. From production to delivery, every step reflects high standards and meticulousness. This has given us great confidence in our projects and left our end-users highly satisfied. They are a reliable partner for our flooring supply needs.

Strong Customization Capabilities, Meeting Diverse Needs

As a company focused on high-end design projects, we have very specific requirements for flooring patterns and functionalities. Qingdao Huanju can provide hundreds of color film patterns and flexibly adjust thickness and wear layer. This has greatly expanded our design possibilities and helped us successfully complete numerous complex projects.

Efficient Production, Guaranteeing On-Time Delivery

In the construction industry, time is money. Qingdao Huanju’s production efficiency and delivery speed are highly reliable; they consistently deliver on time, even with our large-volume orders. Their clear communication and professional logistics arrangements ensure our project timelines remain unaffected, making them a prime example of efficient B2B collaboration.

Frequently Asked Questions

A: Qingdao Huanju New Material Technology Co., Ltd. was established in 2017, possessing eight years of experience in SPC flooring production.

A: Our products are exported globally, including the USA, Europe, and Southeast Asia. Our SPC flooring products comply with CE certification. Additionally, we can provide SGS reports for clients to review specific product performance parameters.

A: The production process of SPC flooring primarily involves five main steps: extrusion, UV coating, cutting/grooving, silent pad lamination, and packaging. Our extrusion process has 4 fully automated production lines, capable of producing at least 25000 square meters of 4mm thick SPC flooring in 24 hours. The UV coating process has a capacity of at least 5000 square meters in 8 hours, and the cutting/grooving process has a capacity of at least 7000 square meters in 8 hours.

A: We offer a variety of common thickness options ranging from 3.5mm to 7.5mm. Common wear layer thicknesses include 0.2mm, 0.3mm, 0.4mm, and 0.5mm, and we can also customize thicker wear layers for high-end or commercial clients. Surface textures include flat, deep grain (0.15mm-0.48mm), shallow grain, and leather textures.

A: Each roll of color film is approximately 1000 meters, so if clients require custom color film patterns, the MOQ is 1000 meters. We offer hundreds of color film patterns, including designs that mimic solid wood, marble, and carpet textures, as well as special texture designs (such as grass patterns, modern minimalist textures, etc.).

Still Have Questions?

You’re very welcome to visit our factory.

So contact us freely now! We’re 24*7 hours online.