Stone Plastic Composite (SPC) flooring represents a structural transformation, featuring a hyper-dense, rigid core created from a precise marriage of natural stone and virgin polymers. This engineered leap delivers a floor that is fundamentally more stable, immune to thermal expansion, and virtually impervious to water damage.

The Foundation of Functionality: SPC Raw Materials

The exceptional durability of SPC is rooted in a balanced blend of Virgin PVC Resin (for structure), Fine Limestone Powder (for density and stability), and specialized Stabilizers and Plasticizers (to ensure longevity and impact resistance).

From Aggregate to Aesthetic: The 5 Core Manufacturing Stages

The entire process of transforming raw material into finished SPC planks can be summarized into five key, high-tech stages:

1. Compounding & Core Extrusion (Building the Foundation)

Raw materials are precisely compounded and then fed into powerful extruders. Under intense heat and pressure, the mix is pressed through calenders, forming a continuous, monolithic, and ultra-dense SPC Rigid Core sheet. This foundational stage guarantees the floor’s dimensional stability.

2. Hot Press Lamination (Fusing the Layers)

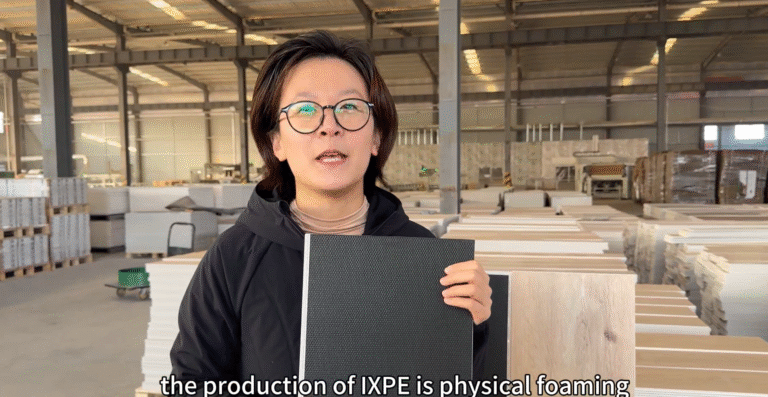

The rigid core sheet is sent through a high-temperature, high-pressure lamination machine. Here, the Decorative Print Film, the protective Wear Layer, and the Polymer Bottom Layer are all permanently fused to the SPC core. This is the moment the floor gets its look and its primary defense shield.

3. Stabilization & UV Curing (Securing the Structure)

After lamination, the large sheet undergoes a mandatory thermal stabilization cycle (annealing) of heating and cooling to relieve internal stress, ensuring the planks will never warp. Simultaneously, a durable, clear UV Top Coat is applied and cured, sealing the surface for superior stain and scratch resistance.

4. Precision Profiling (Creating the Click System)

The stabilized sheet is cut into individual planks and fed into state-of-the-art profiling equipment. Using extreme precision, the patented click-lock mechanisms are milled onto all four sides of every plank. This step is critical for a gap-free, easy, and glueless installation.

5. Final Inspection & Packaging (Quality Assurance)

Every finished plank is subjected to rigorous Quality Control (QC) checks for dimensional accuracy, color consistency, and lock integrity. Finally, integrated underlayment is applied (if required), and the planks are boxed, labeled, and prepared for global shipment.

Partnering for Success: Your Global Manufacturing Advantage

Partnering for Success: Your Global Manufacturing Advantage

Huanju is an industry-leading manufacturer focused exclusively on high-performance vinyl flooring solutions. Our facilities are equipped with the most advanced SPC production lines, supported by a fully independent testing laboratory to guarantee material consistency. We have secured long-term partnerships as a designated OEM supplier for numerous international brands, exporting our superior products worldwide.